Parts Of An Excavator

페이지 정보

본문

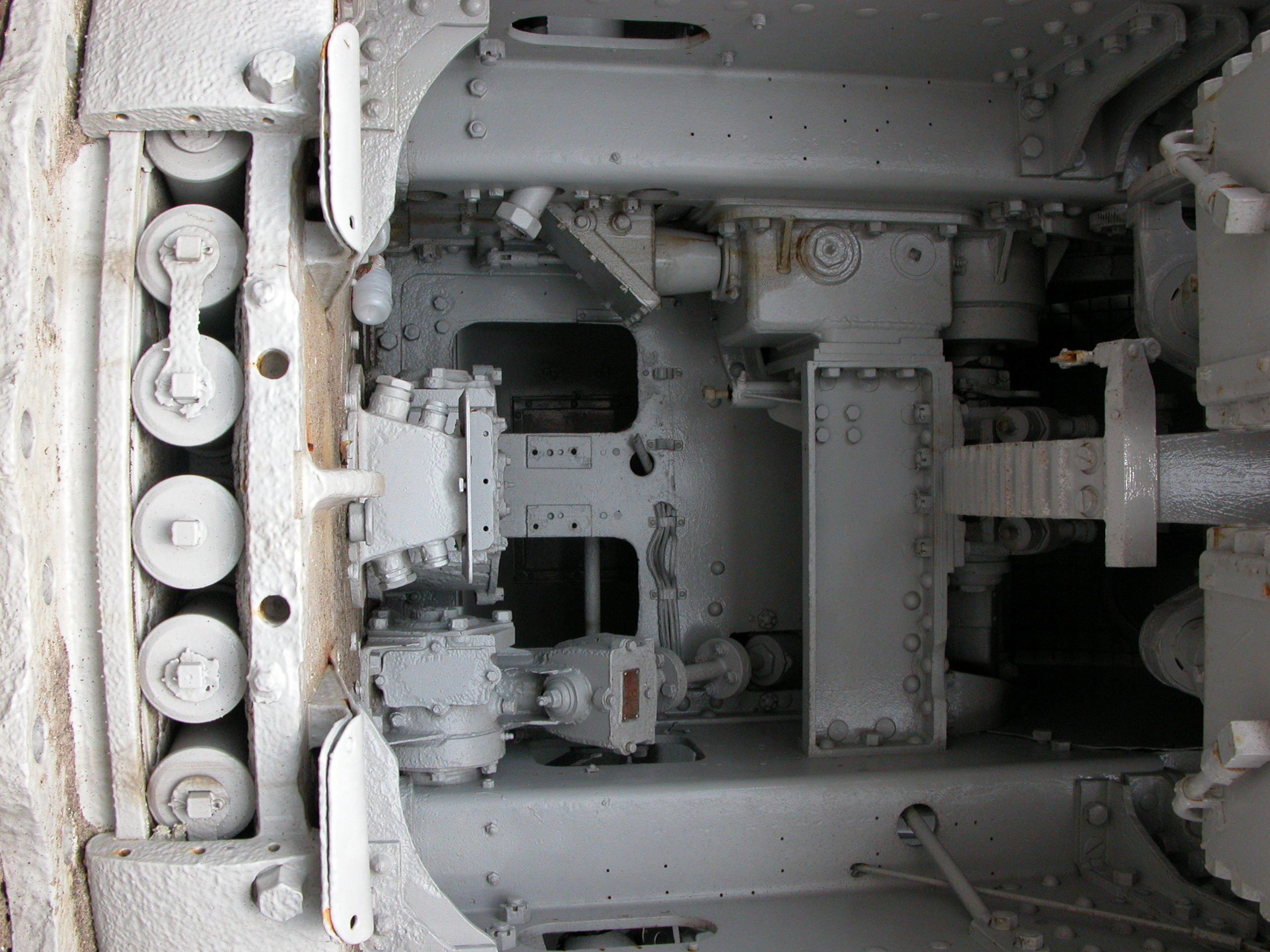

Operators need to decide on an arm that is highly effective and sturdy enough to handle the requirements of the duty at hand whereas providing the necessary reach and stability. Excavator hydraulics and controls play a vital role within the machine’s operation. The hydraulic system supplies the facility wanted to perform varied duties, Cummins Engine Repair resembling digging, lifting, and transferring materials. The controls give the operator precise command over the excavator’s movements and functions. There are two primary varieties of hydraulic programs used in excavators: open-center and closed-middle systems. In an open-middle system, hydraulic fluid is constantly flowing by way of the system, even when the excavator is just not in use. This results in a less efficient system, because the pump is constantly working. Its hits are more constant, however they lack the finesse and management of its hydraulic cousin. Ultimate for breaking massive, flat surfaces like concrete slabs, the drop hammer might be seen as a brute force strategy. Whereas effective, it doesn’t fairly dance with the grace of a hydraulic breaker. Enter the hydraulic breaker, a classy artist within the realm of demolition.

On the subject of understanding all the elements of an excavator, they will simply be damaged down into three important sections: the undercarriage, cab and arm/increase. Let’s uncover the parts of an excavator and their functions! The excavator undercarriage is the underside section of an excavator that houses numerous shifting components. The tracks of the excavator, usually made with steel-reinforced rubber, move the machine. Some excavators are wheeled but perform similarly to these with tracks. The track frame is where the excavator tracks attach to the undercarriage, functioning similarly to axels. Observe pads will help stop excess noise, vibration and injury, in addition to present better traction during operation. Monitor chains are what enable an excavator to maneuver efficiently. Finally, it is important to follow the manufacturer’s pointers and proposals for the specific hydraulic breaker being used. The manufacturer’s directions will provide worthwhile info on the proper operation, maintenance, and security precautions for the hydraulic breaker. Following these pointers will make sure the environment friendly and safe operation of the gear. In conclusion, operating a hydraulic breaker requires adherence to important security measures.

Most all of, the HB and KHB series of hydraulic breaker have been of the right this moment common nitrogen fired, or nitrogen assist design, which uses nitrogen within the back head of the hammer that acted as a bowstring. The bowstring was pulled back by hydraulic power. The early Kent hydraulic hammers additionally featured on board accumulators, which might assist to absorb spikes coming from the carrier’s auxiliary hydraulic system and redirect a few of that power. We're not sure who invented this design for hoe rams or rockbreakers, but it is used in our Gorilla Hydraulic Breakers, Atlas Copco, Okada, NPK, BTI, Chicago Pneumatic (CP) and more. How do I maintain my Excavator Dredge Pump Attachment? Regular upkeep includes checking hydraulic lines for leaks, inspecting the pump for put on and injury, and cleansing the intake and discharge areas to forestall clogging. Additionally it is essential to observe the manufacturer’s particular upkeep pointers to make sure optimum efficiency and longevity. Are there environmental issues when utilizing an excavator dredge pump? Sure, it is essential to contemplate the environmental impression of dredging activities. Measures should be taken to reduce turbidity and stop injury to aquatic habitats. Acquiring necessary permits and adhering to native environmental rules is also essential.

- 이전글Hidden Answers To Blog Revealed 24.10.13

- 다음글Which Sports Supplements Are Worth Taking? 24.10.13

댓글목록

등록된 댓글이 없습니다.